Today's HoursWednesday 8:00 am - 5:30 pm

| Monday | 8:00 am - 5:30 pm |

| Tuesday | 8:00 am - 5:30 pm |

| Wednesday | 8:00 am - 5:30 pm |

| Thursday | 8:00 am - 5:30 pm |

| Friday | 8:00 am - 5:30 pm |

| Saturday | Closed |

| Sunday | Closed |

Specials

Weidemann - 1880

|

The multifunctional Hoftrac Compact design, low centre of gravity, tight turning radius and powerful performance – these features have characterised the Hoftrac series for years and still determine the immense success of the machines. The Hoftracs effortlessly fulfil any work task and work quickly, flexibly and safely – a Hoftrac is simply always ready for use. |

|

The Weidemann benefits at a glance

The backbone of the Weidemann design. The legendary articulated pendulum joint. All four wheels remain in constant contact with the ground and the machine moves with maximum traction. In addition, the machine has unrivalled manoeuvrability. |

|

Quality creates added value. The powder coating is a key feature of the Weidemann quality standard. In contrast to the conventional wet painting, it greatly increases the service life and is more efficient and also environmentally friendly in the process. |

|

The drive via the planetary axle increases the torque on the wheel and thereby improves the shear force. Due to the optimal ratio between the shear force and machine capacity, you work flexibly and economically at the same time. |

|

If necessary, the up to 100% connectable differential lock offers you maximum traction shear forces and keeps the tire wear low (switched off during normal operation). |

|

Weidemann always installs two lift cylinders in all Hoftrac and wheel loader models. This guarantees that the load distribution is always optimally transferred to the loading arm. In addition, the entire loading system gains stability. The size of the lift cylinder is adapted to the respective size of the machine. |

|

The angled loading arm is designed to be particularly sturdy and torsion resistant. At Weidemann, the kinematics are adjusted to the size of the machine - this ensures optimal balances of power for every machine. The P-Z kinematics is a combination of P-kinematics and Z-kinematics. It allows significant lifting and shearing forces and has a finely co-ordinated parallel motion in the process. |

|

At a full steering stop, the front and rear carriage of the machine touch. With Weidemann, this area is particularly well-protected by the stainless steel steering stops and the machine's paint is not damaged. This provides for value preservation! |

|

Use your machine as a multi-tool - you have a wide selection of attachments available for your Weidemann. Here you can find which attachment in what size is right for your machine » |

|

The optimal tires for every subgrade - you have a wide selection of different tires available for your Weidemann. You can find which tires are right for is right for your machine » |

|

Select your driver’s cab

Maximum safety that is state of the art. As a standard, Weidemann installs a canopy with a restraint system on all Hoftrac models. The canopy and the restraint system for the operator meet the current European machinery directive (2006/42/EC) for ROPS and FOPS protection.

|

|

The spacious cabin meets the current European machine directive (2006/42/EC) according to ROPS and FOPS protection and offers a great deal of headroom and freedom of movement. The complete glazing provides the operator with an excellent overview of the attachment and the entire working area. |

|

Optimum ease of servicing

Regularly lubricating all lubrication service points of the machine is essential for correct and effective maintenance and therefore for the value preservation of the machine. In order to save time and facilitate the work, the lubrication service points are always in an easily accessible position at Weidemann. Optionally, a central lubrication system is available that takes over the lubrication for you. |

|

Unique at Weidemann: The tiltable driver's cab allows for easy access to the engine, hydraulic system and electrical system. Maintenance and service made extremely easy! |

|

Unique at Weidemann: The tiltable cab allows for easy access to the engine, hydraulic system and electrical system. Maintenance and service made extremely easy! |

|

The engine hood can be opened backwards with just one handle for regular service and maintenance jobs. The hydraulic oil tank, air cleaner, engine oil filling, oil-level dipstick and coolant are therefore easily and quickly accessible. |

|

Weidemann machines have short hydraulic hose lengths - the hoses are split in several places. If a hydraulic hose needs to be exchanged, the entire hose in the hydraulic circuit does not need to be exchanged, but rather just the affected part. This speeds up work enormously and saves money. |

|

A workplace that motivates

The steering column can be individually adjusted according to the operator's request. This ensures that every operator can work with the machine ergonomically and fatigue-free. |

|

Perfect control of the machine and functions via a joystick of the latest generation. The innovative joystick with ergonomically arranged, illuminated touch controls creates user friendliness and multi-functionality. |

|

Plenty of legroom, clearly arranged instrument clusters, a comfortable driver's seat and an optimal view of the attachment. A workplace that motivates and fully supports the operator. |

|

The working environment in the cabin is excellent, thanks to an efficiently working heating and ventilation system with a fan, fresh air filter and well-placed air nozzles. For particularly hot outdoor temperatures, we recommend the air conditioning option. |

|

Vibrations and impacts are absorbed by the machine. Your body is very well-protected and you also work for a longer time relaxed and fatigue-free - and are therefore simply more focused. |

|

Brake-inch pedal

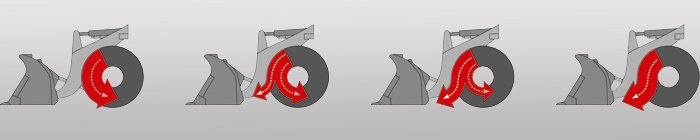

The hydrostatic all-wheel drive is combined with the brake pedal for Weidemann machines. By "inching," this makes it possible to crawl until the travelling operation comes to a standstill. With the partially depressed brake-inch pedal , you can drive slowly in crawl speed at full engine speed precisely to the millimetre and at the same time lift quickly. If the pedal is pressed further, the machine is braked. The advantage of the brake-inch pedal lies in the optimal power-output distribution of the engine rated power. In addition, it is not possible to stall the machine. |

|

New wheel loader generation

We at Weidemann have already successfully completed stages I to IIIA for pollutant reduction in recent years. However, new, more strict thresholds are waiting in stages IIIB and IV (tier 4 interim and tier 4 final) to be met. However, since we would like to adapt our machines to the new legal situation and also continue to develop our machines, we have put a great deal of development work and expertise into the new machine types. |

|

The most important functions always in sight. With the digital display, for the first time the active features are displayed in the driver's cab, for example the activated differential lock or electrical functions. |

|

The sometimes drawn-out search for hidden errors belongs to the past. With the new machine models 1880 and 5080, the Weidemann diagnostic and analysis system wedias is used to now quickly and clearly evaluate many features, such as the driving function, telescoping function, the 3rd and 4th control circuit, engine data as well as electrical functions. Error messages in the display immediately notify the driver of possible errors and make a rapid response possible. Thanks to the exact designation of the error number, the dealer can come to the machine prepared and with the right spare parts. The subsequent error analysis by the trained dealer simplifies further diagnosis and troubleshooting enormously. This saves time, money and nerves. |

.jpg)