Today's HoursWednesday 8:00 am - 5:30 pm

| Monday | 8:00 am - 5:30 pm |

| Tuesday | 8:00 am - 5:30 pm |

| Wednesday | 8:00 am - 5:30 pm |

| Thursday | 8:00 am - 5:30 pm |

| Friday | 8:00 am - 5:30 pm |

| Saturday | Closed |

| Sunday | Closed |

Specials

Weidemann - T4512

|

Next Generation - The Telehandler T4512 The compact Weidemann telehandler T4512 offers a unique combination of lifting height, width and machine capacity: A lifting height of 4.5 m enables you to carry out a whole range of stacking and loading tasks. It also makes light work of getting over most high-sided constructions. With a substantial payload of 1.25 tonnes, any type of large bale or weight of material poses no problem. The machine’s compact dimensions - just 1.56 m wide and a little less than 2 m high - make it a real showstopper. These “ideal dimensions” enable the telehandler to pass through narrow thoroughfares and be manoeuvred in tight spaces, making it ideal for indoor work. All these factors have contributed to more than 10 years of success of our T4512 on the market - and now we’re taking things up a gear: Converting the engine of the telehandler T4512 to comply with exhaust emission stage V has meant a full redesign of this successful machine. You can now look forward to new product features that will make your everyday work even easier! |

|

Exhaust emission stage V

The entry-level engine of the T4512 has a power output of 18.4 kW / 25 hp. The great advantage of this is that it complies with exhaust emission stage V, whilst dispensing with the need for any exhaust gas treatment. This engine version is also ideal for users who require relatively lower operational hours from their machine. A 33.3 kW / 45.3 hp engine is available as an option. This has been developed for professional applications. With this machine, conversion to exhaust emission stage V has been achieved by installing a diesel particle filter (DPF) together with a diesel oxidisation catalyst (DOC). This technology does not require any input of urea solution (DEF). The entire engine unit, complete with exhaust gas treatment, comes from Yanmar, ensuring that all components are perfectly compatible and that the machine automatically regenerates at the relevant operating temperature. |

|

Electronically-controlled traction drive - Weidemann ecDrive With the new electronically-controlled traction drive, ecDrive (Electronic Controlled Drive), this machine can be driven and used to suit any requirement. This is possible thanks to 4 different drive modes implemented by Weidemann.

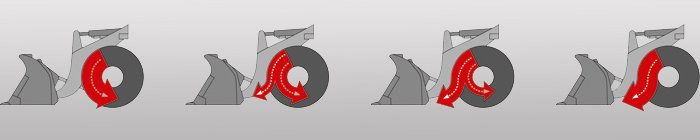

Auto mode: Ensures the usual 100% performance of the machine. Eco mode: Once the vehicle has reached the desired speed, the engine speed reduces to 2200 rpm, thus reducing noise and saving fuel. The two other optional drive modes are designed specifically for use by hydraulically-driven attachments or for the optimised execution of the Y-loading cycle: Attachment mode: This mode provides perfect support for the use of attachments. In this mode, the manual throttle is used to set the diesel engine’s rpm, with the driving speed being controlled by the drive pedal or speed control unit. These features enable speeds to be finely set at increments of 0.10 km/h via the display. This ensures a constant feed for the attachment. If the load on the attachment is too great (e.g. various clippings in front of a mulcher), the machine automatically reduces the speed to ensure that the attachment functions with the highest possible performance. Once the load is removed, the machine can be switched back to its pre-set speed. This is done using a speed control unit. However, if you want to drive forward or reverse more quickly, you can override the unit at any time by engaging the foot pedal to accelerate the machine, even to its maximum speed, if required. M-drive mode: This mode is ideal for optimising the execution of Y-loading cycles. In this mode, the manual throttle is used to set the diesel engine’s rpm, with the driving speed or control pressure being controlled by the drive pedal. This means there is no longer any need for inching, thus greatly supporting the execution of fast Y-load cycles.

The new electric handbrake features an auto-hold as well as a hill-hold function. The brake engages automatically when the machine comes to a halt, when moved into neutral or when the operator leaves the cab. The electric handbrake is released automatically when the machine is set in motion using the accelerator. Naturally, the brake can also be engaged or released manually using the switch. Enhanced comfort and security for the operator. |

|

The Weidemann benefits at a glance

Thanks to the all-wheel steering and the undivided frame, Weidemann telehandlers are particularly manoeuvrable and very stable. The low centre of gravity of the machine further enhances its stability. |

|

Quality creates added value. The powder coating is a key feature of the Weidemann quality standard. In contrast to the conventional wet painting, it greatly increases the service life and is more efficient and also environmentally friendly in the process.

|

|

The VLS (Vertical Lift System) enables a fluid working principle and, through a partially automated telescoping movement, facilitates working in a complex operating environment. The near-vertical lifting or lowering movement of the machine improves its stability. The vls has proven itself well in the area of agriculture and our innovation has received several international awards. |

|

The telescopic arm is designed to be sturdy and stable and is placed in the centre of the machine, which causes little distortion. Parallel guidance is hydraulic. The sliding components in the inner tube of the telescopic arm require no maintenance. All important hydraulic lines are ideally protected against external influences. With our compact Weidemann telehandlers, you reach amazing lifting heights with the best stability and compact dimensions. |

|

Weidemann telehandlers feature comprehensive and sturdy standard equipment. Depending on the application, the engine, drive, hydraulics or tyres can be individually configured. Your Weidemann is always custom-made. |

|

The drive via the planetary axle increases the torque on the wheel, thereby improving pushing power. Due to the optimal ratio between the pushing power and machine capacity, work is both flexible and economical.

|

|

The connectible 100% differential lock provides maximum traction and thrusting force if necessary. It also minimises wear on tyres (switched off during normal operation). |

|

The optimal tyre to suit any type of surface – that is what we offer! We have a wide selection of different tyres available for your Weidemann. Which tyres are right for your machine? Find out here » |

|

A multi-tool for various applications Whether loading, stacking, pushing, sweeping, mowing or transporting material: Our huge range of different attachments transforms your Weidemann into a universal multi-tool. We have a wide selection of different attachments available for your machine. Which attachment and what size do you need for your machine? Find out here » |

|

Compact design, compact dimensions

The width and height of all compact Weidemann telehandlers is less than 2 metres. This is also what makes them ideal for use in confined areas - their combination of lifting height, width and machine capacity makes them unique. |

|

All telehandlers in our compact series have particularly small inner radii. The manoeuvrability this achieves is what makes these machines all-rounders, wherever they are used. |

|

The operator’s central seating position and the fully glazed cab with its deep-drawn windows ensure excellent all-round visibility over the entire working area. |

|

The Weidemann telehandler T4512 can easily be transported on a trailer. This gives machines the versatility to be moved around quickly from job to job.

|

|

Weidemann also offers a special feature to assist coupling and uncoupling hydraulically operated attachments: The knob for pressure release of the 3rd control circuit is easily accessible from the outside on the telescopic arm. This makes it quicker and more efficient to change the various attachments. It works when the ignition is on or the engine is running. The smooth, flat face couplings are also fitted as standard. |

|

Optimum ease of servicing

The engine bonnet with gas compression springs can be opened upward with just one handle for regular service and maintenance work. The hydraulic oil tank, air cleaner, engine oil filling, oil-level dipstick and coolant are therefore easily and quickly accessible - a big plus for convenience. |

|

A motivating workplace

With the new T4512, operators can enjoy significantly improved working environment as a result of the installation of a new and efficient heating and ventilation system, complete with fan, fresh-air filter and well-placed air nozzles. For particularly hot outdoor temperatures, we recommend the air-conditioning system option. The large upper door pane and the rear windscreen can both be fitted with gap ventilation. And, just like its predecessor, the upper door pane also opens through 180° and can be locked in position behind the cab. |

|

More space in a cab that has been designed and developed according to the latest findings in safety technology and ergonomics. Plenty of leg-room, clear colour-coded layout of combi-instruments, comfortable operator’s seat and optimal view of attachments. All the operator’s controls are within easy reach and the optimally positioned display ensures that the operator has constant visibility of key machine information. A working area that motivates and fully supports the operator. |

|

Visibility to the right is often poor with many telehandlers. Weidemann ensures good visibility, courtesy of the large-sized right window, the low positioning of the telescopic arm and the steeply sloping engine bonnet. This means you always have optimal visibility of the area to the right of the machine and of the right mirror. |

|

The benefits of a telehandler come to the fore when it comes to stacking loads high. Visibility above the machine is also crucial to ensure the load is positioned safely when working at a height. With Weidemann telehandlers, the cab and windscreen are designed so that the operator can see the load at all times, even at maximum lifting height. The three windscreen wipers (front, rear and roof) ensure a crystal-clear view at all times! |

|

The joystick sits securely and comfortably in your hand. The control is both sturdy and sensitive. This means you always have the machine and its key functions under control. The continuous function of the 3rd control unit is easy to activate using a rocker switch on the keypad; it can then be proportionally controlled with ease using the joystick, using the freely adjustable control wheel which can be moved in both directions. The thumb-wheel can be used for proportional telescoping, enabling working speed to be individually adjusted. Both electrical functions can also be operated momentarily or latching on the joystick. Neither electrical function depends on the other, meaning that the operator can configure them individually. |

|

The operator can climb into the cab with a single step, courtesy of the machine’s low height and low headroom construction. |

|

Both the height and the angle of the steering column and steering wheel can be individually set according to the operator’s requirements. This ensures ergonomic comfort for operator, enabling them to work without becoming fatigued. |

|

Brake-inch pedal

In Weidemann machines, the hydrostatic 4-wheel drive is combined with the brake pedal. This enables the machine to “inch” its way forward and creep to a standstill. By lightly depressing the brake-inch pedal, the operator can drive slowly in crawl speed with millimetre precision and lift quickly whilst the engine is running at full speed. Fully depressing the pedal applies the brakes to the machine. The advantage of the brake-inch pedal is the optimal distribution of engine output. It is also impossible to stall the machine. |

.jpg)