- Monday 8:00 AM - 5:30 PM

- Tuesday 8:00 AM - 5:30 PM

- Wednesday 8:00 AM - 5:30 PM

- Thursday 8:00 AM - 5:30 PM

- Friday 8:00 AM - 5:30 PM

- Saturday Closed

- Sunday Closed

Wacker Neuson Wheel Loader WL60

Model

Wheel Loader WL60

Category Name

Agriculture

Year

2025

Sale Type

New

Manufacturer

Wacker Neuson

Quantity

0

Manufacturer Qty

0

Overview

Specifications

highlights

features

downloads

Documents

Wheel Loader WL60: High productivity and ideal comfort

The WL 60 wheel loader offers an extremely comfortable cab and a wide variety of options. The operating philosophy is designed for ergonomics. Everything is well within the operator’s reach, which ensures fatigue-free work even over a longer period of time. The high flow load-sensing performance hydraulics with 150 l/min flow rate is the strongest in the 6 t class, also ensuring more operating comfort and less fuel consumption by the machine.

Model

Wheel Loader WL60

Category Name

Agriculture

Year

2025

Sale Type

New

Manufacturer

Wacker Neuson

Highlights

30/40 km/h speed

|

Clear 3.5-inch digital display

|

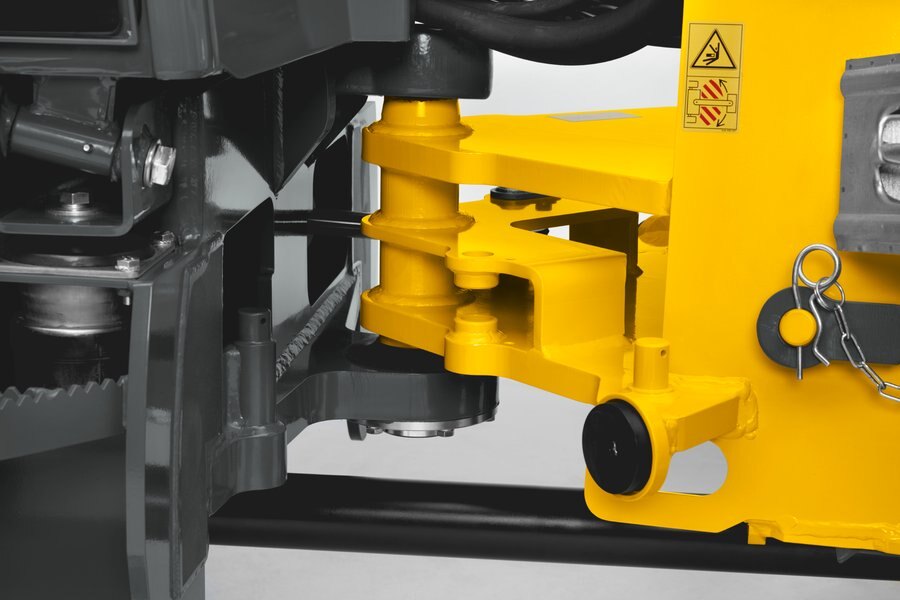

The wheel loader as an attachment carrier

|

Comfortable working environment

|

Joystick console spring-mounted on the operator's seat

|

Features

Safety

|

Maintenance

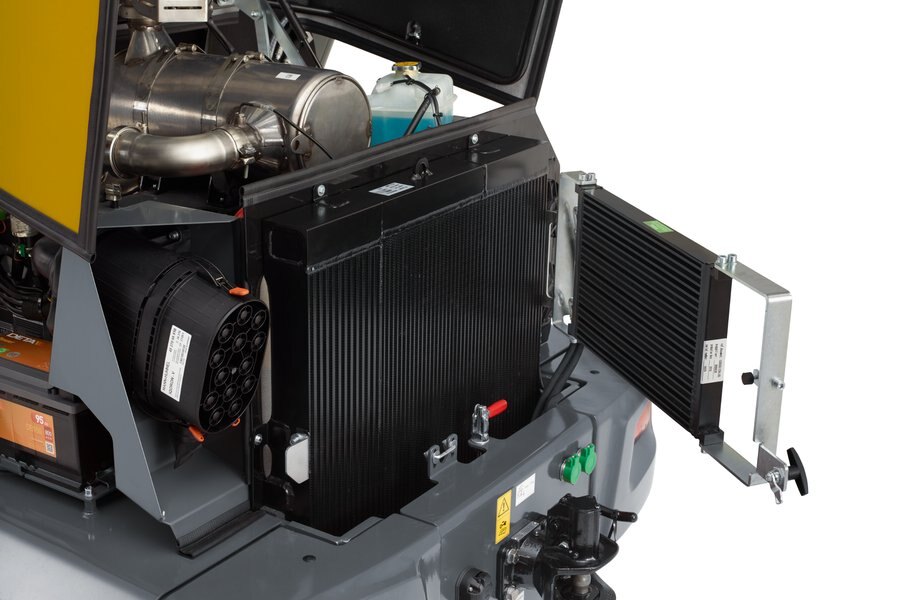

Easily accessible machine components.

|

Tiltable cabin and optimal service access

|

Split hydraulic hoses

|

Efficiency

Inch brake pedal: Engine output where it is needed.

|

Rear hydraulic connections

|

Performance

Compact dimensions for optimal maneuverability

|

30 km/h speed

|

Quality

High-quality powder coating

|

Print

Print Contact Us

Contact Us Share this

Share this