Weidemann 2080T

|

|

|

Specifications

|

Model |

2080T

|

Category Name |

Equipment

|

Year |

2025

|

|

Sale Type |

New

|

Manufacturer |

Weidemann

|

Odometer |

km

|

|

Price |

Contact for price CAD

|

|

|

|

|

Description

2080T Telescopic wheel loaders - Versatile entry-level model

Our customers describe the compact, but very powerful, tele wheel loader 2080T as an absolute performer on their farms. A tele wheel loader is particularly suitable whenever more lifting height is required. This is because, in addition to high functionality, great working comfort and excellent safety standards, these machines demonstrate a significantly increased lifting height and reach. The telescopic arm is robust and stable’ the parallel guidance is hydraulic. All important hydraulic lines are located inside and are protected from external influences. The drive, via planetary axles, increases the torque at the wheel and thus significantly improves the thrust. Through the optimum ratio of thrust and machine performance, you can work flexibly and very economically with the tele wheel loader 2080T. The machine becomes an all-rounder with a wide range of suitable attachments, which are ideal for the different tasks in the various industries.

|

|

|

|

HIGHLIGHTS

|

Highlights

Robust Telescopic Arm Robust Telescopic Arm

- Compared to the normal wheel loader with loading swing arm, telescopic wheel loaders have a telescopic arm and thus a significantly increased lifting height and reach. These machines are characterized by features such as high maneuverability and good all-round visibility thanks to a central seating position and high lifting capacity.

- The telescopic arm is robust and sturdily built, and the parallel guidance is hydraulic. All-important hydraulic lines are located internally and are protected against external influences. This increases the longevity of the machine.

- The telescopic boom combines the advantages of an articulated machine with those of a telescopic loader. In this way, a high overload height and reach are achieved even with an articulated machine.

|

Very good service access due to tiltable cab Very good service access due to tiltable cab

- The cab can be tilted to the side in a few easy steps. This allows uncomplicated access to the engine, hydraulic system and electrics. This greatly simplifies the monitoring and maintenance of the machine.

- Easy and quick maintenance maximizes the availability of the machine and optimizes the operating costs.

|

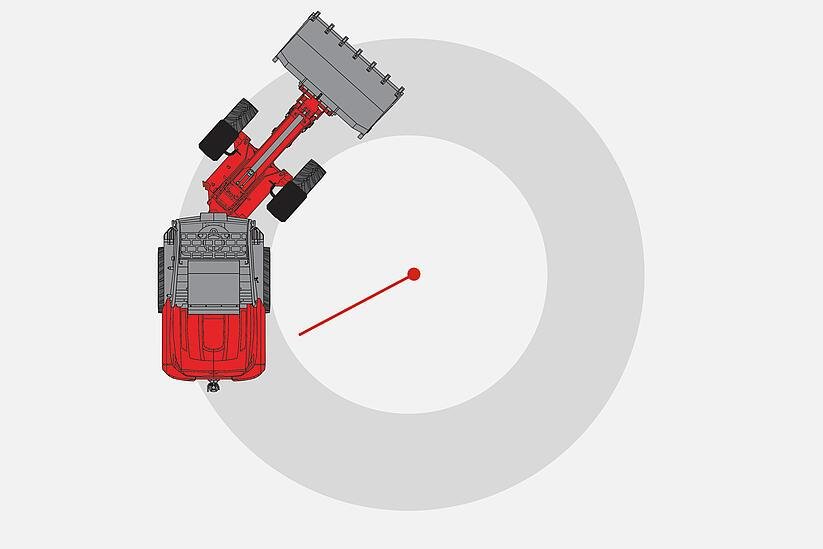

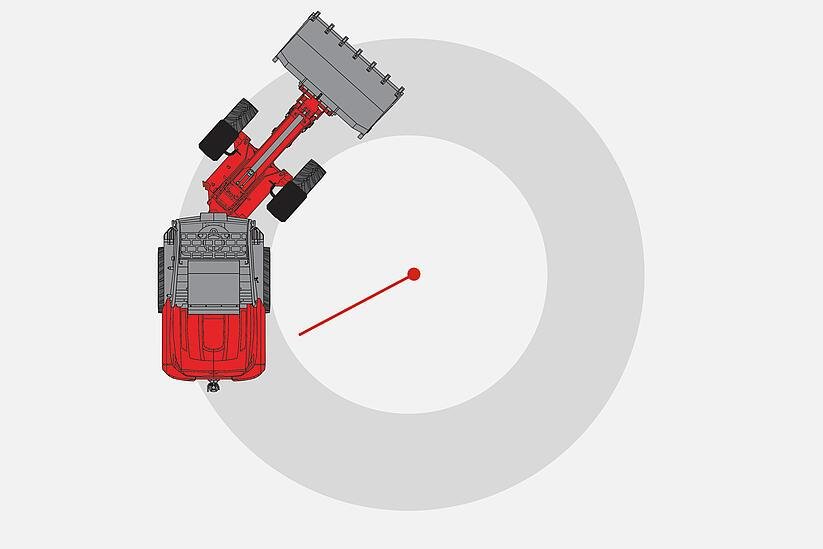

Compact dimensions for optimal maneuverability Compact dimensions for optimal maneuverability

- Compact dimensions and directional stability ensure optimum mobility and high maneuverability of the machine.

- The dimension of the machine are ideal. This makes it possible to work even in confined spaces.

|

Ergonomic Joystick Ergonomic Joystick

- The joystick can be held securely and comfortably. The control is, both, direct and sensitive. Thus the operator always has the machine and the most important functions under control.

- In addition to standard functions such as selecting the direction of travel and the speed level, many other functions such as the differential lock, the 3rd and 4th control circuit, High-Flow and all electric functions can be operated via the joystick. This enables comfortable one-handed operation of attachments.

- Concentrating the most important function on the joystick ensures comfortable working even over longer periods of time. This also increases overall efficiency when working with the machine.

|

Joystick console spring-mounted on the operator's seat Joystick console spring-mounted on the operator's seat

- The joystick console is mounted on the operator's seat and cushions in response to vibrations. If the operator's seat is adjusted to the operator's needs, the joystick console is always in the perfect position as well. This provides added comfort and ergonomics for the operator.

- The joystick console and the operator's seat form a single unit. This ensures that the operator's arm position remains constant while working with the machine. This increases the operator's comfort and enables them to work productively and in a focused manner for longer.

|

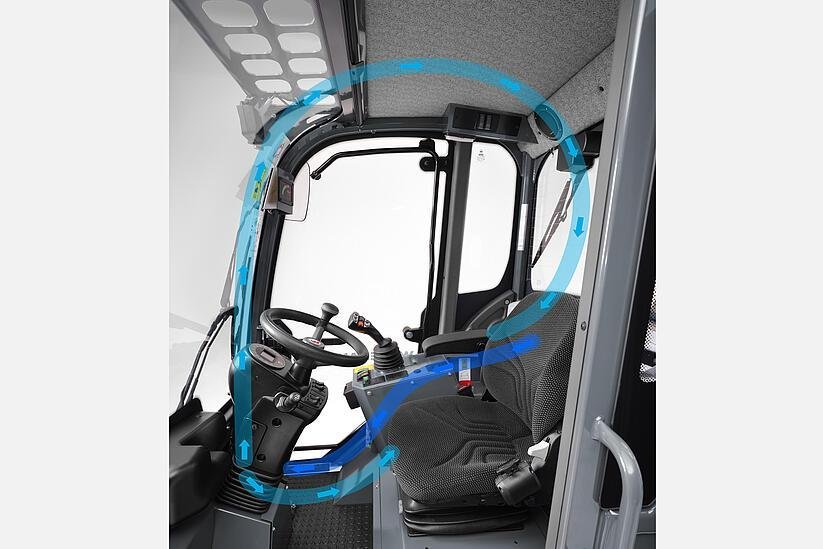

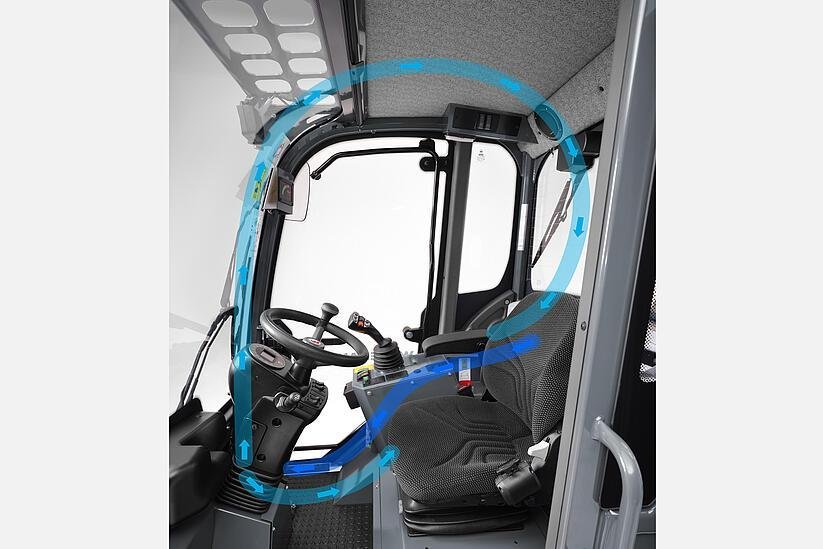

Air-conditioning system Air-conditioning system

- The optional air conditioning system ensures a pleasant working climate inside the cab when outside temperatures are warm. It ensures a high airflow and impresses with its optimized cooling capacity. The operating element for the control and the air nozzles are always in the best possible position.

- The air conditioning system increases the comfort for the operator. It enables fatigue-free work as it reduces the strain on the operator in warm outdoor temperatures.

|

|

|

STANDARD ENGINE DATA

|

Standard_engine_data

| Engine manufacturer |

Deutz |

| Motor type |

TD 2.9 L4 S5 |

| Cylinder |

4 |

| Drive output |

45 kW |

| Drive output |

61 HP |

| At max. rpm |

2,300 rpm |

| Cylinder capacity |

176.97 in³ |

| Type of coolant |

Water |

| Exhaust standard level |

V |

| Exhaust aftertreatment |

DOC/DPF |

|

|

ENGINE DATA OPTION 1

|

Engine_data_Option_1

| Engine manufacturer |

Deutz |

| Motor type |

TCD 2.9 L4 S5 |

| Cylinder |

4 |

| Drive output |

55.4 kW |

| Drive output |

75 HP |

| At max. rpm |

2,300 rpm |

| Cylinder capacity |

176.97 in³ |

| Type of coolant |

Water/charge air |

| Exhaust standard level |

V |

| Exhaust aftertreatment |

DOC/DPF |

|

|

ELECTRICAL SYSTEM

|

Electrical_system

| Operating voltage |

12 V |

| Battery |

100 Ah |

| Alternator |

95 A |

|

|

WEIGHTS

|

Weights

| Operating weight |

10,141 lb |

| Tipping load with bucket – machine straight, loading frame horizontal |

5,983 lb |

| Tipping load with bucket – machine pivoted, loading frame horizontal |

4,982 lb |

| Tipping load with bucket – machine straight (extended) |

3,444 lb |

| Tipping load with bucket – machine pivoted (extended) |

2,855 lb |

| Tipping load with pallet fork – machine straight, loading frame horizontal |

5,254 lb |

| Tipping load with pallet fork – machine pivoted, loading frame horizontal |

4,407 lb |

| Tipping load with pallet fork – machine straight (extended) |

3,208 lb |

| Tipping load with pallet fork – machine pivoted (extended) |

2,674 lb |

|

|

DRIVER'S CAB

|

|

|

|

FILLING LEVELS

|

Filling_levels

| Tank capacity for fuel |

19.81 US gal |

| Tank capacity for hydraulic oil |

13.21 US gal |

|

|

DRIVE SYSTEM

|

Drive_system

| Type of drive |

hydrostatic |

| Drive unit |

universal joint shaft |

| Speed levels |

2 |

| Axle |

PA 1200 |

| Travel speed Standard |

0-12,43 mph |

| Travel speed Option 1 |

0-17,40 mph |

| Operating brake |

Hydrostatic drive acting on all 4 wheels (wear-free) |

| Parking brake |

Service and parking brake in the drive train acting on all 4 wheels |

| Differential lock |

100% front axle rear axle |

|

|

HYDRAULIC SYSTEM

|

Hydraulic_system

| Drive hydraulics working pressure (max.) |

6527 psi |

| Work hydraulics discharge volume (max.) |

15,19 (19,55) gpm |

| Work hydraulics working pressure (max.) |

3408 psi |

|

|

KINEMATICS

|

Kinematics

| Lifting cylinder |

1 |

| Tipping cylinder |

1 |

| Quick change system |

hydraulic |

|

|

STEERING

|

Steering

| Steering type |

Hydraulic activated articulated pendulum steering |

| Steering cylinder |

1 |

| Oscillating angle |

± 12 degree |

|

|

NOISE CHARACTERISTIC VALUES

|

Noise_characteristic_values

| Average sound power level LwA (cabin) |

99.9 dB(A) |

| Guaranteed sound power level LwA (cabin) |

101 dB(A) |

| Specified sound pressure level LpA (cabin) |

74 dB(A) |

|

|

OTHER INFORMATION

|

|

|

|

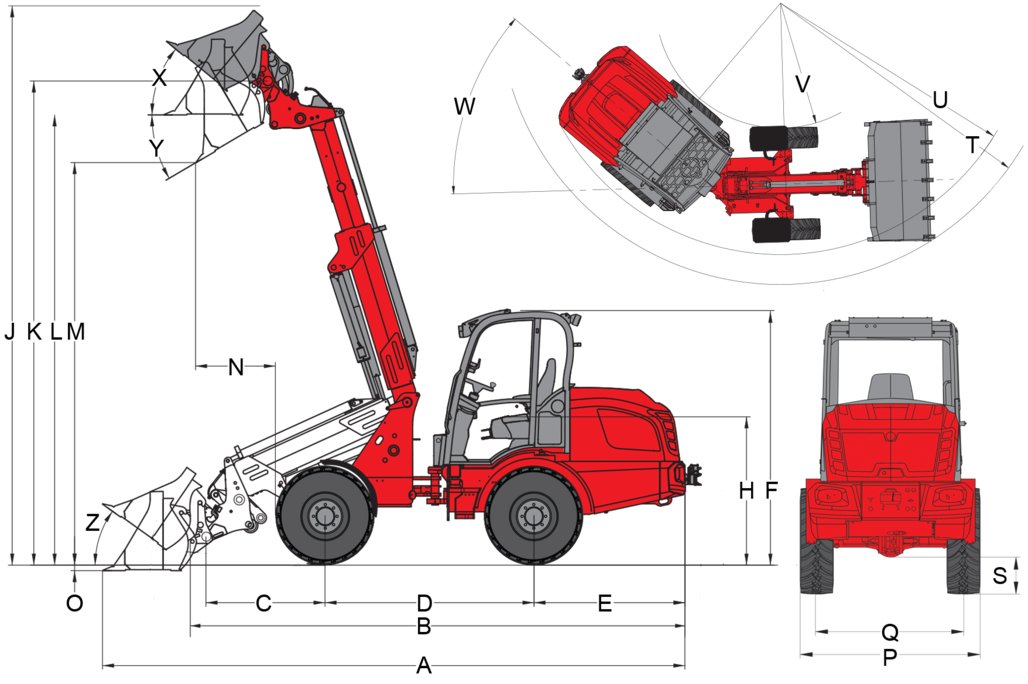

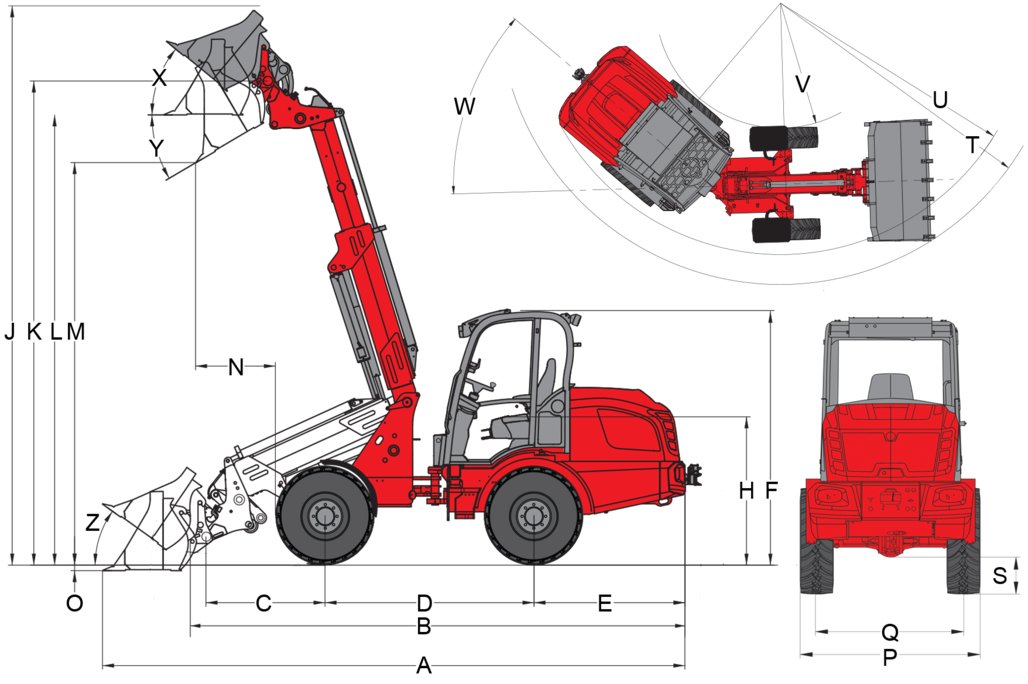

DIMENSIONS

|

Dimensions

|

| |

|

Telescopic arm (Z-kinematics) |

| - |

Standard tires |

11.5/80 - 15.3 AS ET40 |

| A |

Total length |

216.5 in |

| B |

Total length without bucket |

165.0 in |

| C |

Bucket pivot point (to center of axle) |

26.8 in |

| D |

Wheel base |

80.7 in |

| E |

Rear overhang |

55.9 in |

| F |

Height with cab raised |

92.9 in |

| F |

Height with cab lowered |

100.0 in |

| H |

Seat height |

56.3 in |

| J |

Total working height |

200.0 in |

| K |

Bucket pivot point (max. lift height) |

168.9 in |

| L |

Load-over height telescopic arm extended |

155.1 in |

| M |

Dumping height telescopic arm extended |

133.9 in |

| N |

Reach (at M) |

35.0 in |

| O |

Digging depth |

5.9 in |

| P |

Total width |

55.5 in |

| Q |

Track width |

44.1 in |

| S |

Ground clearance |

11.8 in |

| T |

Maximum radius |

150.8 in |

| U |

Radius on the outer edge |

130.7 in |

| V |

Inner radius |

68.1 in |

| W |

Articulation angle |

45 ° |

| X |

Rollback angle at max. lift height |

40 ° |

| Y |

Dumping angle |

33 ° |

| Z |

Rollback angle on ground |

32 ° |

|

|

|

EDITIONS

|

Editions

2080T

- Cab high 1-door, incl. heating and ventilation

- Seat; fabric; air suspension

- Air-conditioning system

- Lighting according to Road Traffic Regulations

- 4 Work lights LED Performance

- Rotating beacon LED (yellow)

- Diesel engine Deutz, TCD 2.9 L4, 55.4 kW / 75 HP

- Axle PA940 planetary axle

- Manual throttle

- Hand inching

- 28 km/h (speed increase)

- Tires Alliance 570 425/55 R 17 AS ET-40

- Load arm shock absorption

- Quick hitch plate ALO (Euro)

- Unpressurized return line, front

- Work hydraulic (74 l/min) large pump

- 3rd control circuit proportional

- Counterweight floor plate

- Electrical socket front 3-pin for dual function

- EquipCare available

Options

- Quick hitch plate Skidsteer

- Tires 11.5/80-15.3 AS ET40, Machine width: 1,410 mm / 4.63'

- Tires 12-16.5 Sure Trax ET0 BKT, Machine width: 1,530 mm / 5.02'

- Special paintwork RAL single colour - in place of WM red

- Special paintwork RAL multi-colour

|

|

|

DOWNLOADS

|

|

|

Robust Telescopic Arm

Robust Telescopic Arm Very good service access due to tiltable cab

Very good service access due to tiltable cab Compact dimensions for optimal maneuverability

Compact dimensions for optimal maneuverability Ergonomic Joystick

Ergonomic Joystick Joystick console spring-mounted on the operator's seat

Joystick console spring-mounted on the operator's seat Air-conditioning system

Air-conditioning system