- Monday 8:00 AM - 5:30 PM

- Tuesday 8:00 AM - 5:30 PM

- Wednesday 8:00 AM - 5:30 PM

- Thursday 8:00 AM - 5:30 PM

- Friday 8:00 AM - 5:30 PM

- Saturday Closed

- Sunday Closed

Wacker Neuson Telehandler TH412

Model

Telehandler TH412

Category Name

Agriculture

Year

2025

Sale Type

New

Manufacturer

Wacker Neuson

Quantity

0

Manufacturer Qty

0

Axle

PAL 1155

Battery

77 Ah

Overview

Specifications

highlights

features

downloads

Documents

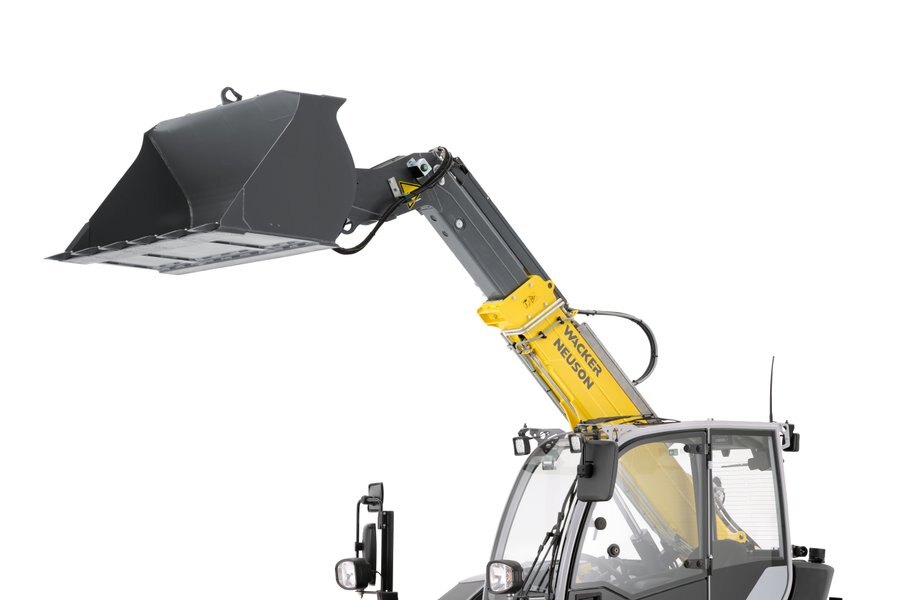

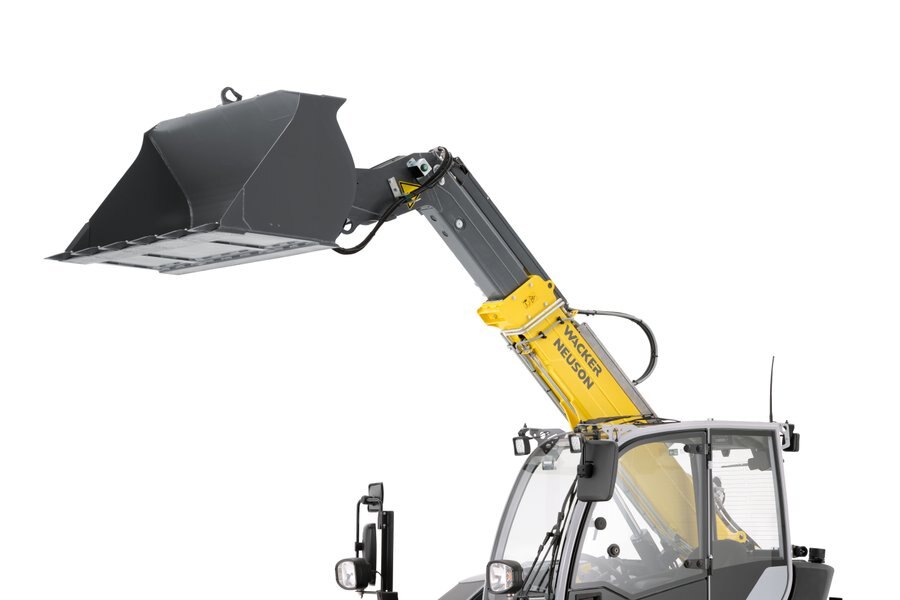

Telehandler TH412: Compact and powerful

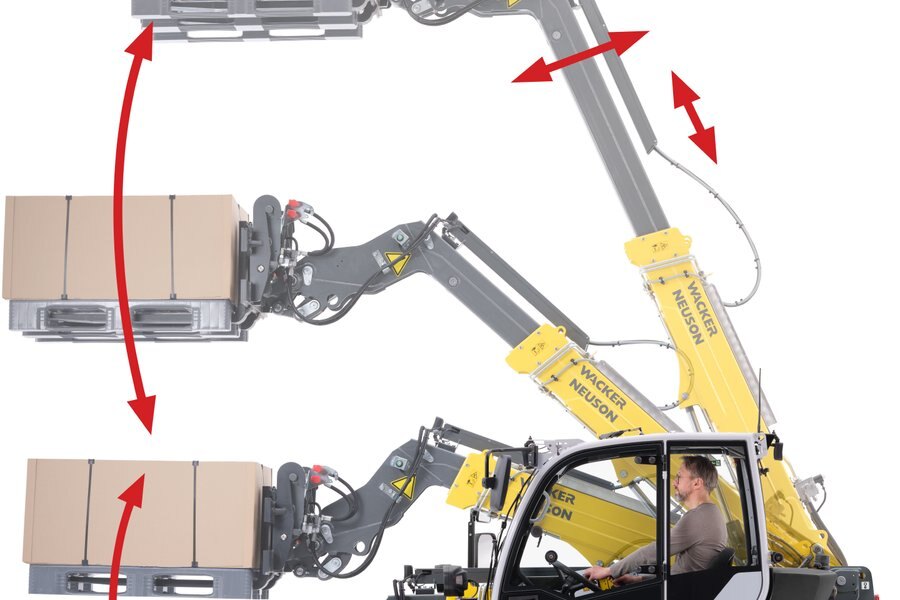

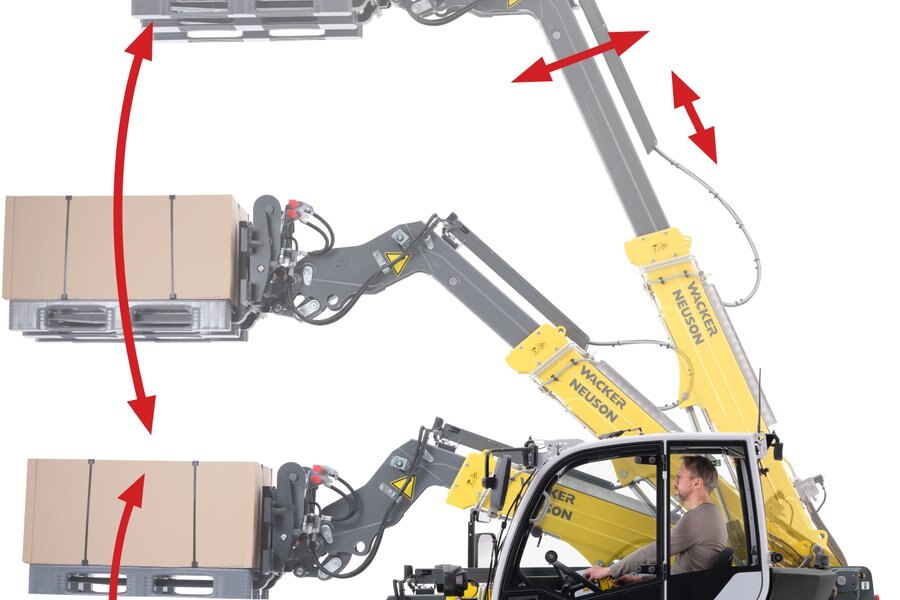

All wheel steering, low centre of gravity and excellent stability distinguish the TH412 telehandler. The integrated driver assistance system VLS (Vertical Lift System) ensures safety, while also increases the operator comfort. The electronically regulated drive system with various operator modes enables an externally productive work operation with the machine. Thanks to its low operating weight and very compact dimensions, the TH412 can be transported on a car trailer without any problems. This makes its flexible for use in many different areas.

Model

Telehandler TH412

Category Name

Agriculture

Year

2025

Sale Type

New

Manufacturer

Wacker Neuson

Axle

PAL 1155

Battery

77 Ah

Cylinder

3

Alternator

80 A

At Max. Rpm

2,600 rpm

Drive Output

44.7 HP

Speed Levels

2

Type Of Drive

Electronically controlled

Payload (max.)

2,756 lb

Type Of Coolant

Water

Cylinder Capacity

95.69 in³

Engine Manufacturer

Yanmar

Exhaust Standard Level

V

Highlights

Electronically controlled drive system

|

Electric parking brake

|

VLS (Vertical Lift System)

|

Colour-oriented operating concept

|

Compact and powerful

|

Features

Safety

|

Excellent all-round visibility

|

Good illumination of the work area

|

Maintenance

Optimum ease of servicing

|

Efficiency

Engine standard

|

Engine option

|

Comfort

Comfort cabin

|

Ergonomic joystick

|

Efficient change of attachments

|

Downloads

| PI Sheet TH412 | Download |

Print

Print Contact Us

Contact Us Share this

Share this